Technology

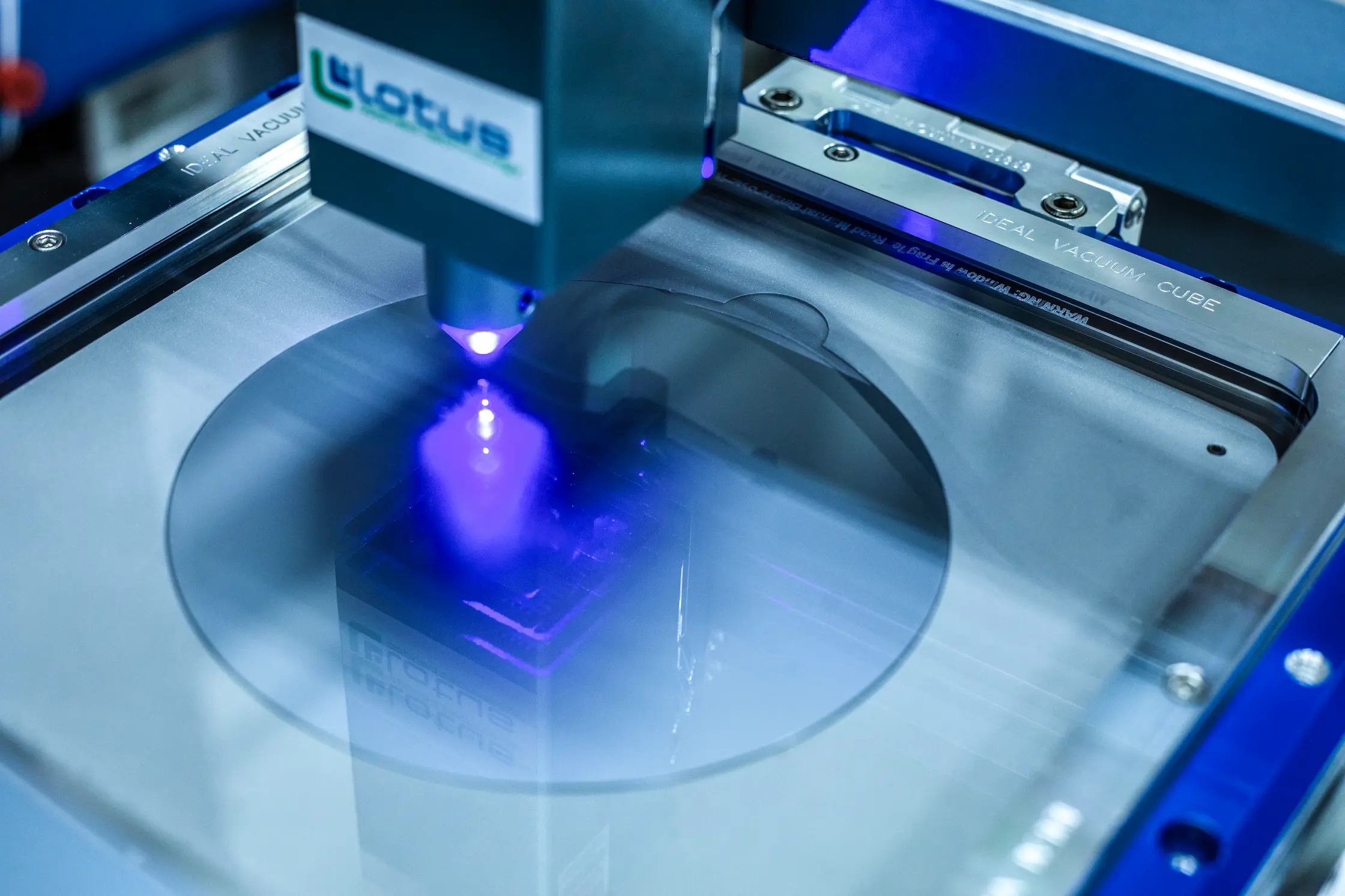

VortexTM ALD

VortexTMALD is a rotary batch technology that uses rotation of a disc or cylinder to transport substrates.

Higher Batch

Deposition Speeds

Several angstroms per second, which is faster than many oxide sputtering processes.

Low Particulate

Generation

No coating anywhere in the chamber except on the substrates and carrier surface.

Low

Materials Costs

Precursors are consumed only on the substrate track – exhausted precursor material may be captured and re-used.

Low Temperature Processing

Leveraging the advantages of simple DC plasma, our processes are available at 100°C or lower, even down to room temperature.

...plus all the benefits of Conventional ALD!

VortexTM ALD can deliver five ALD cycles per second in its single-cycle configuration - and up to 20 when paired with PlasmaShield technology.

Greatly simplifies zone separation

Enables the use of a simple DC plasma

Eliminates the time required for precursor introduction, saturation, and purge

Our VortexTM ALD technology revolutionizes batch ALD processing.

Instead of pulsing and purging precursors from a static substrate in a single chamber, the substrate is transported by rotation to the various precursor and purge zones of the reactor.

This eliminates the time required for precursor introduction, saturation, and purge with each ALD cycle. Further, Lotus’ patented Radical Enabled ALD process, incorporating Precursor “Separation” by Radical Deactivation technology, greatly simplifies zone separation in the reactor, and enables the use of a simple DC plasma for PEALD processing.

For applications requiring even higher deposition rates, our PlasmaShield technology may be employed to enable up to 4 ALD cycles per revolution. This technology can be scaled from small reactors for research and small area manufacturing, to meter-scale substrates.

Vortex Batch ALD

High-volume production batch using rotating discs or cylinders to transport substrates.

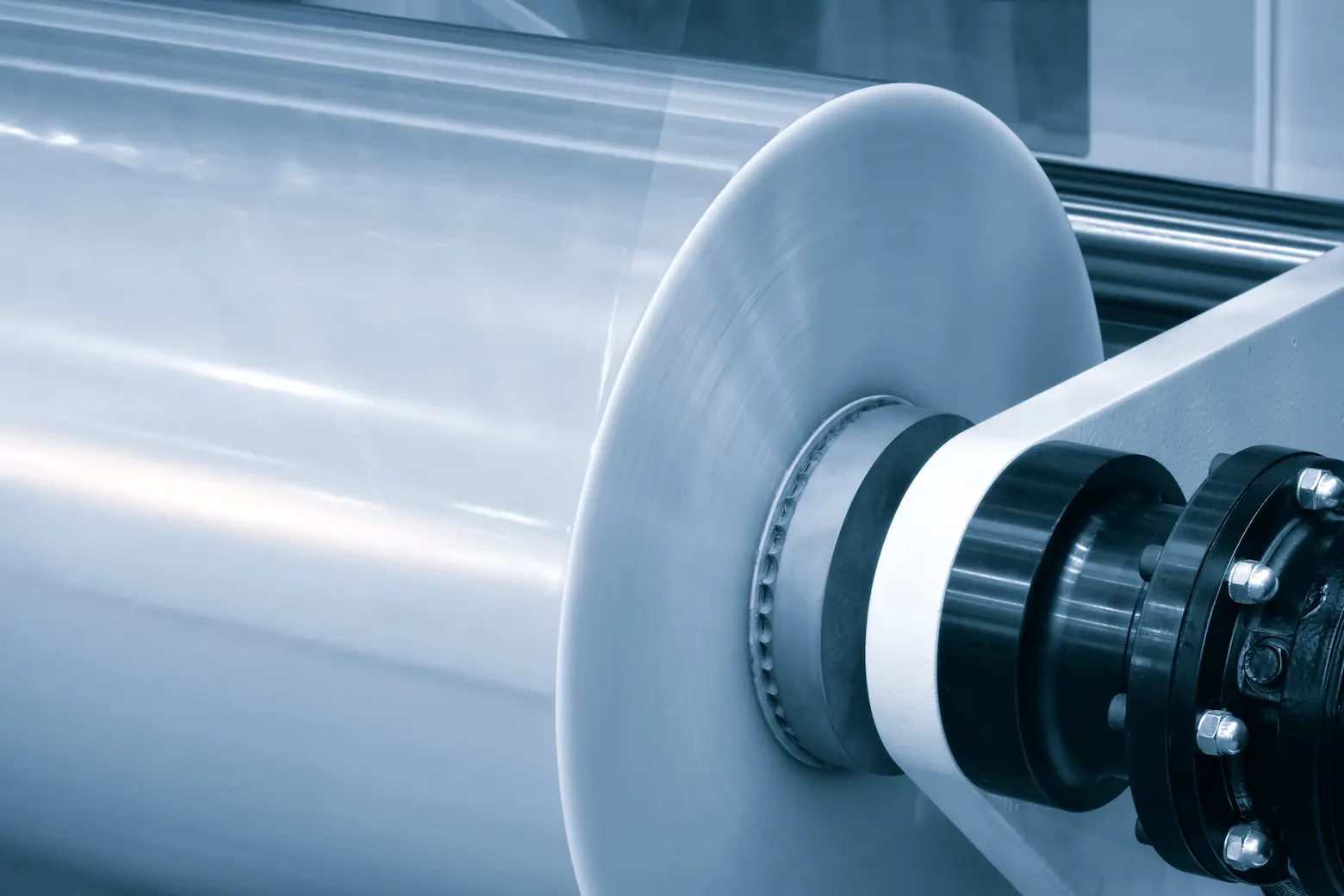

TransFlexTM

Roll to Roll ALD

Continuous coating creation for large-area substrate films and foils.

Rapid Thermal ALD

High-speed processing utilizing ultrafast lasers for precise patterns.

%20(1).jpg)

PlasmaShieldTM

Ultra-precise deposition zones with PlasmaShield technology.

Sheet-to-Sheet Processing Platform

PlasmaShieldTM technology with linear substrate movement for large area processing.

In-Line Roll to Roll Platform

A flexible Roll-to-Roll platform for moderate speed PEALD with straightforward web handling.

Want to work with us?

If you're looking to learn how ALD could work in your application, we'd love to talk.